Shade Variation

Variations in shade are inherent in all kiln fired products and are one of the Natural Characteristics of Ceramic and Porcelain Tiles.

Shade variation can occur in all types of kiln-fired clay products including tiles. Consequently, each production run of tiles is given a shade number, which is printed on the outside of the carton. This number should be given to the tile supplier if additional tiles are required.

It is the tile installers responsibility to check the shade numbers on the boxes before installation commences. If different shade numbers are discovered, the tile installer must inform the client. If several areas, wall or floor, are being covered with the same tile, it may be possible to use different batches in separate areas.

Many contemporary ceramic tiles are designed to imitate the appearance of natural materials like timber and stone products, which frequently vary substantially in appearance.

Tile manufacturers use the latest digital ink-jet printing technologies to create surfaces which reflect that natural variation. Ink-jet printing processes allow manufacturers to deliberately produce a multiplicity of patterns within one batch, which ensures that the finished products vary in appearance, just like the natural surface finishes they seek to emulate.

As a result of shade variation the shade of sample products displayed in tile outlets may vary from the products which are delivered.

There are two main types of shade variation:

Colour variation from sample to actual

This is the toughest shade variation to anticipate. This variation, also known as dyelot or tonality, is inherent in producing a unique product. Due to the nature of the production process and materials used, variations in colour is almost inevitable between production lots. (This is also the case with bricks, pavers, carpet, textiles and vinyl etc.)

Shades may be similar to those obtained in previous productions but they will rarely, if ever, be the same, therefore it is best to buy all material to be installed at the same time. (Ideally tiles from different batches should not be laid together. If for some reason this is to be done, tiles from each batch should be compared for compatibility before installation.)

It is also wise to keep some extra tiles aside, of the same production lot, for any future maintenance.

As ceramic tiles are a kiln fired product display samples are an indication of the tile colour and shade only. Colour and design may vary between sample and actual tiles supplied. Your local tile store will try its best to update its showroom pieces and samples as frequently as possible with the current batch samples, however sometimes they can differ.

It is quite possible that the tile that you select in the showroom will be a different batch to the tile supplied when ordered for pick up or delivery. This is likely due to the time between the moment you selected the tile to the time that the tile arrives in store for pick up or arrives at site. Your local tile store should stress the importance of reviewing a current batch sample were possible and to check the tiles on site before they are laid in case the batch is not acceptable. This will also be case for other materials such as carpet, fabric and timber. It is important because once the tiles are laid, there is no opportunity to return them.

Colour variation from tile to tile

This is the type of variation that the manufacturer intentionally created in the tiles. Manufacturers are making ceramic tiles to resemble natural products (e.g. natural stone). The more the tile looks like stone the more it acquires natural stone characteristics – such as colour, texture and shade variations.

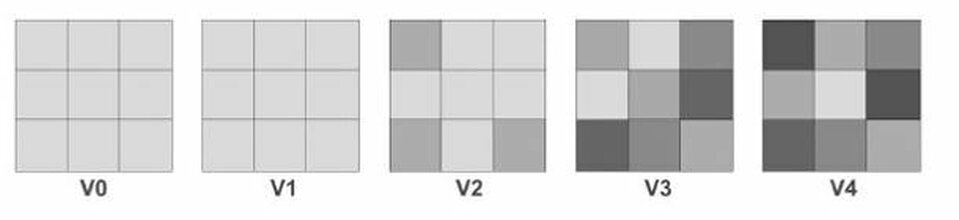

Manufacturers and distributors have started to adopt a colour variation guide. This guide rates ceramic tiles on a four-point scale that ranges from V0 through V4.

Shade variation can occur in all types of kiln-fired clay products including tiles. Consequently, each production run of tiles is given a shade number, which is printed on the outside of the carton. This number should be given to the tile supplier if additional tiles are required.

It is the tile installers responsibility to check the shade numbers on the boxes before installation commences. If different shade numbers are discovered, the tile installer must inform the client. If several areas, wall or floor, are being covered with the same tile, it may be possible to use different batches in separate areas.

Many contemporary ceramic tiles are designed to imitate the appearance of natural materials like timber and stone products, which frequently vary substantially in appearance.

Tile manufacturers use the latest digital ink-jet printing technologies to create surfaces which reflect that natural variation. Ink-jet printing processes allow manufacturers to deliberately produce a multiplicity of patterns within one batch, which ensures that the finished products vary in appearance, just like the natural surface finishes they seek to emulate.

As a result of shade variation the shade of sample products displayed in tile outlets may vary from the products which are delivered.

There are two main types of shade variation:

- Variation from sample to actual (variations between production runs); and

- Variation from tile to tile (intentional variations manufactured into the product).

Colour variation from sample to actual

This is the toughest shade variation to anticipate. This variation, also known as dyelot or tonality, is inherent in producing a unique product. Due to the nature of the production process and materials used, variations in colour is almost inevitable between production lots. (This is also the case with bricks, pavers, carpet, textiles and vinyl etc.)

Shades may be similar to those obtained in previous productions but they will rarely, if ever, be the same, therefore it is best to buy all material to be installed at the same time. (Ideally tiles from different batches should not be laid together. If for some reason this is to be done, tiles from each batch should be compared for compatibility before installation.)

It is also wise to keep some extra tiles aside, of the same production lot, for any future maintenance.

As ceramic tiles are a kiln fired product display samples are an indication of the tile colour and shade only. Colour and design may vary between sample and actual tiles supplied. Your local tile store will try its best to update its showroom pieces and samples as frequently as possible with the current batch samples, however sometimes they can differ.

It is quite possible that the tile that you select in the showroom will be a different batch to the tile supplied when ordered for pick up or delivery. This is likely due to the time between the moment you selected the tile to the time that the tile arrives in store for pick up or arrives at site. Your local tile store should stress the importance of reviewing a current batch sample were possible and to check the tiles on site before they are laid in case the batch is not acceptable. This will also be case for other materials such as carpet, fabric and timber. It is important because once the tiles are laid, there is no opportunity to return them.

Colour variation from tile to tile

This is the type of variation that the manufacturer intentionally created in the tiles. Manufacturers are making ceramic tiles to resemble natural products (e.g. natural stone). The more the tile looks like stone the more it acquires natural stone characteristics – such as colour, texture and shade variations.

Manufacturers and distributors have started to adopt a colour variation guide. This guide rates ceramic tiles on a four-point scale that ranges from V0 through V4.

V0 Monochromatic – The tiles are very uniform, monochromatic colour with little or no variation.

V1 Uniform Appearance (Minimal Variation) – Differences among pieces from the same production run are minimal. The tiles should have uniform appearance and minimal variation.

V2 Slight to Moderate Variation – Clearly distinguishable texture and/or pattern within similar colours. The tiles have a slight to moderate variation in shade, design and texture.

V3 Moderate to Considerable Variation – While the colours present on a single piece of tile will be indicative of the colours to be expected on other tiles, the design and/or amount of colour on each piece may vary significantly. These tiles have moderate to considerable variation in colour,

design, texture and overall appearance.

V4 Substantial Variation – Random colour differences from tile to tile, so that one tile may have totally different colours from other tiles. Thus, the final installation will be unique. The tiles will have a substantial random variation in colour, design, texture and overall appearance.

Markings and Specifications

It is a good idea to keep an empty carton as most of the following key product information is usually printed on the carton:

Blending

As well as variation from batch to batch ceramic tiles can vary slightly within the batch itself. To ensure a successful installation tilers should mix the tiles during laying by working from a number of boxes at the same time.

In this way any small shade variations are blended among the installation evenly resulting in an aesthetically acceptable finish.

Credit: Australian Tile Council

V1 Uniform Appearance (Minimal Variation) – Differences among pieces from the same production run are minimal. The tiles should have uniform appearance and minimal variation.

V2 Slight to Moderate Variation – Clearly distinguishable texture and/or pattern within similar colours. The tiles have a slight to moderate variation in shade, design and texture.

V3 Moderate to Considerable Variation – While the colours present on a single piece of tile will be indicative of the colours to be expected on other tiles, the design and/or amount of colour on each piece may vary significantly. These tiles have moderate to considerable variation in colour,

design, texture and overall appearance.

V4 Substantial Variation – Random colour differences from tile to tile, so that one tile may have totally different colours from other tiles. Thus, the final installation will be unique. The tiles will have a substantial random variation in colour, design, texture and overall appearance.

Markings and Specifications

It is a good idea to keep an empty carton as most of the following key product information is usually printed on the carton:

- product name and reference number

- shade/tone identification

- nominal and work sizes, modular (M) or non-modular

- calibre reference (non-rectified tiles)

- batch identification or production date

- manufacturer’s mark and/or trademark and the country where the tile was manufactured.

- indication of first quality.

- type of tile and reference to the appropriate annex of Annexes A to M within the Standard.

- nature of the surface, i.e. glazed (GL) or unglazed (UGL)

- any surface treatment applied after firing.

- total dry weight of the tiles and carton.

Blending

As well as variation from batch to batch ceramic tiles can vary slightly within the batch itself. To ensure a successful installation tilers should mix the tiles during laying by working from a number of boxes at the same time.

In this way any small shade variations are blended among the installation evenly resulting in an aesthetically acceptable finish.

Credit: Australian Tile Council